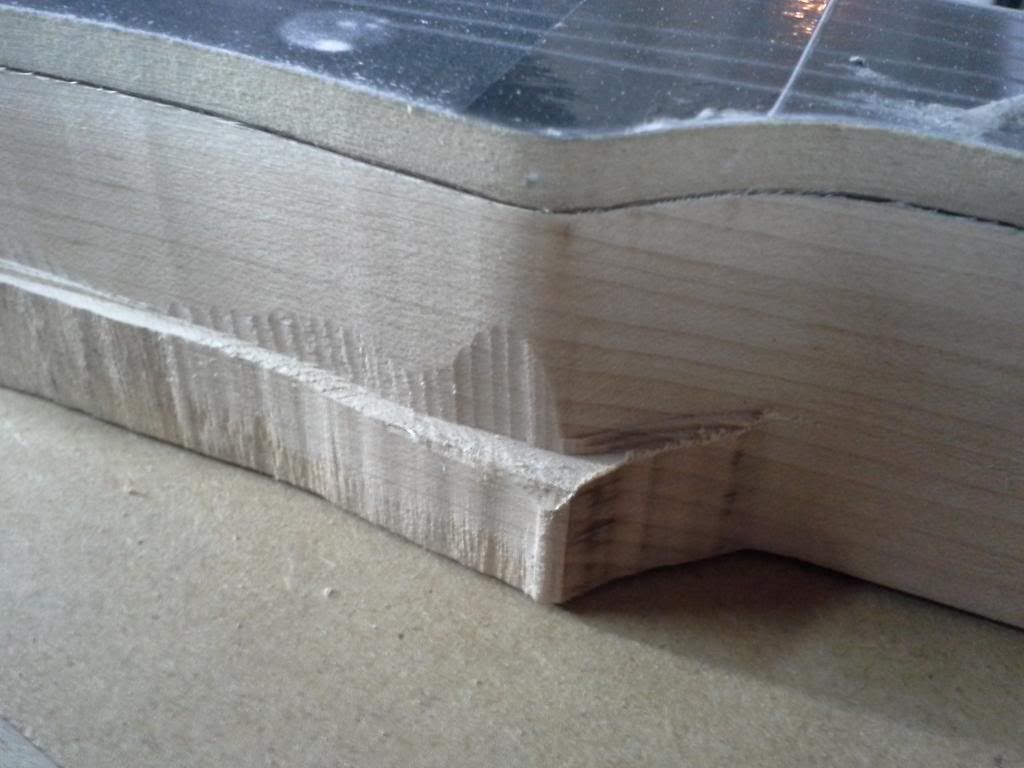

Been there, brother. I don't have pictures of the process, but what I found works best is to route the slot before doing any other cutting on the neck blank. This requires the sides of the blank to be straight and true, of course, but it's much easier to get a straight slot dead center. The slot doesn't interfere with any of the rest of the neck build, either.

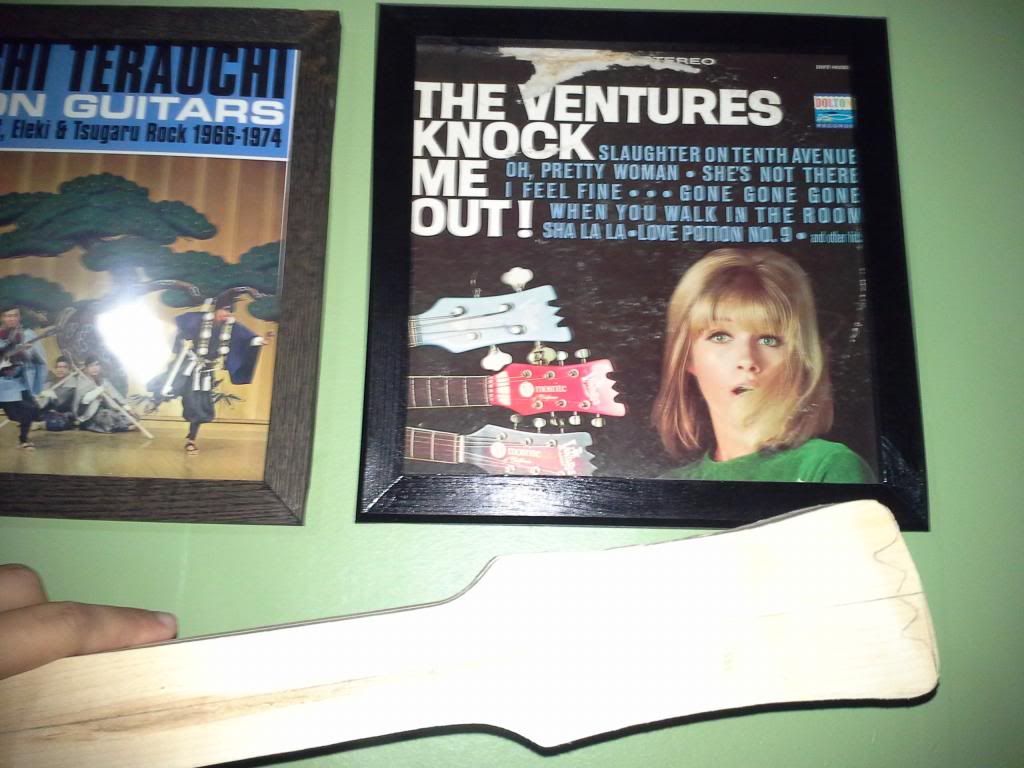

Mark a centerline on your neck blank where you want the slot to run. You'll want to extend this line all the way around the blank, from end to end. This makes lining up the blank on your table much easier. On the heel end of your blank, mark where you want the truss rod slot to end. Again, wrap this line all the way around the blank so you can see it while feeding the blank through your jig.

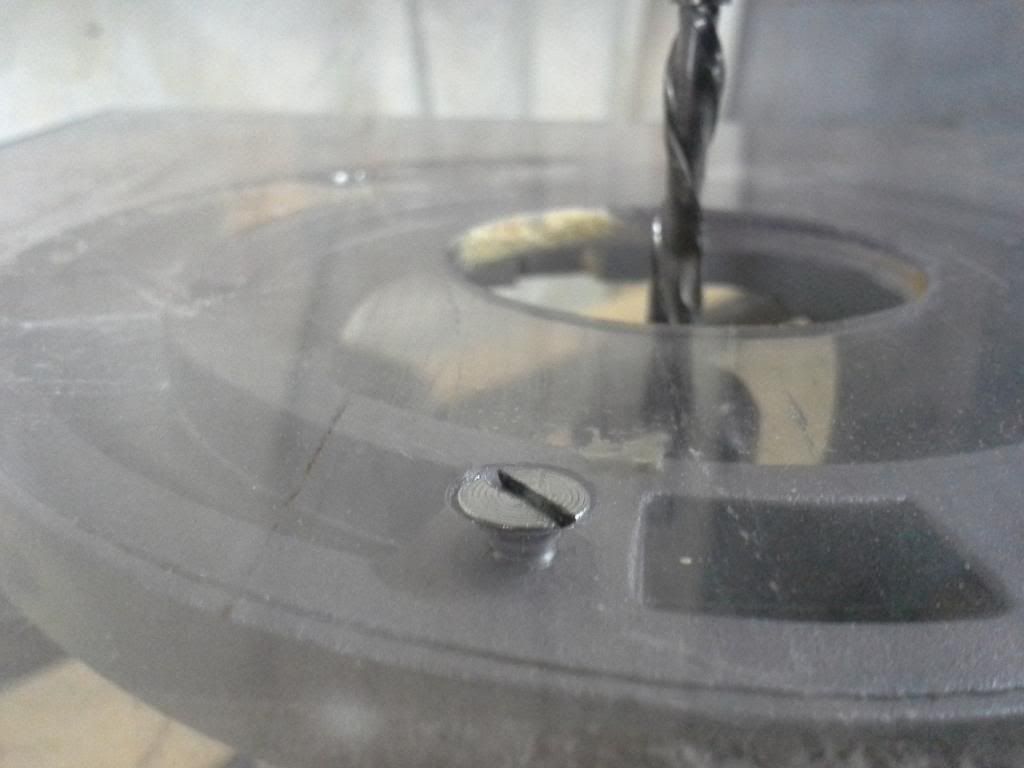

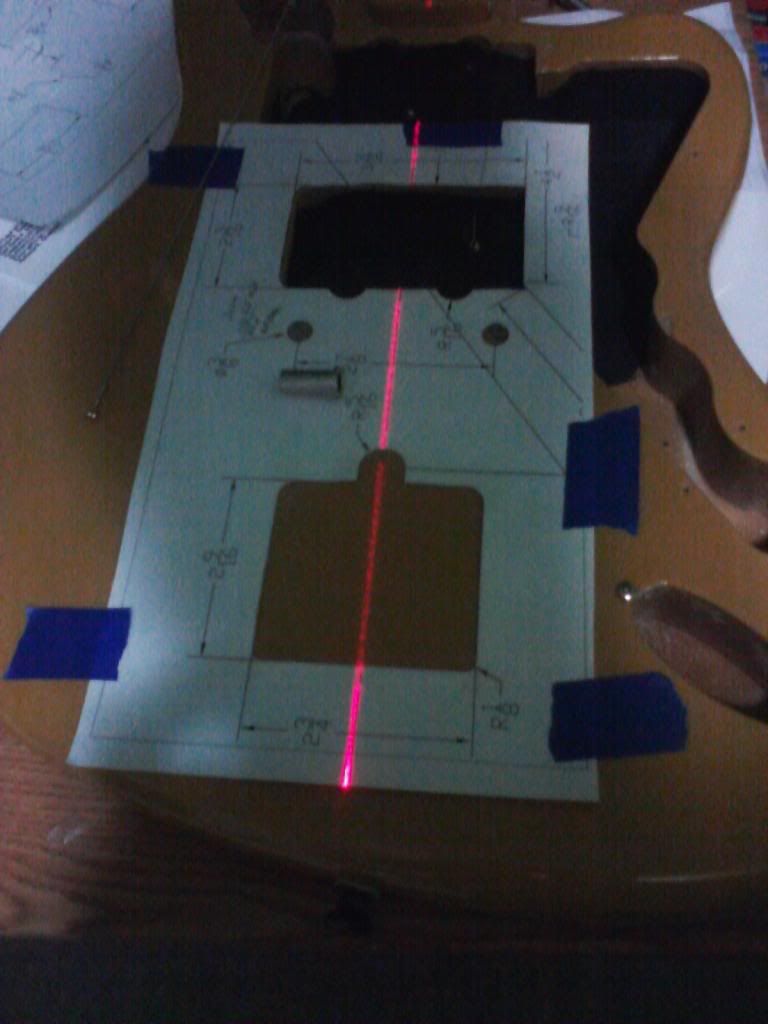

Set up your router table with two of these cutting guide clamps (or something similar)

clamped to the top so the router bit will ride dead center of your blank. The easy way to do this is to take your pre-marked blank and sandwich it between the two clamps with your hands. Then arrange the clamp-blank-clamp sammich so the centerline on the blank is centered on the router bit. Clamp the clamps down and make sure the neck blank slides smoothly between them and is still centered on the bit.

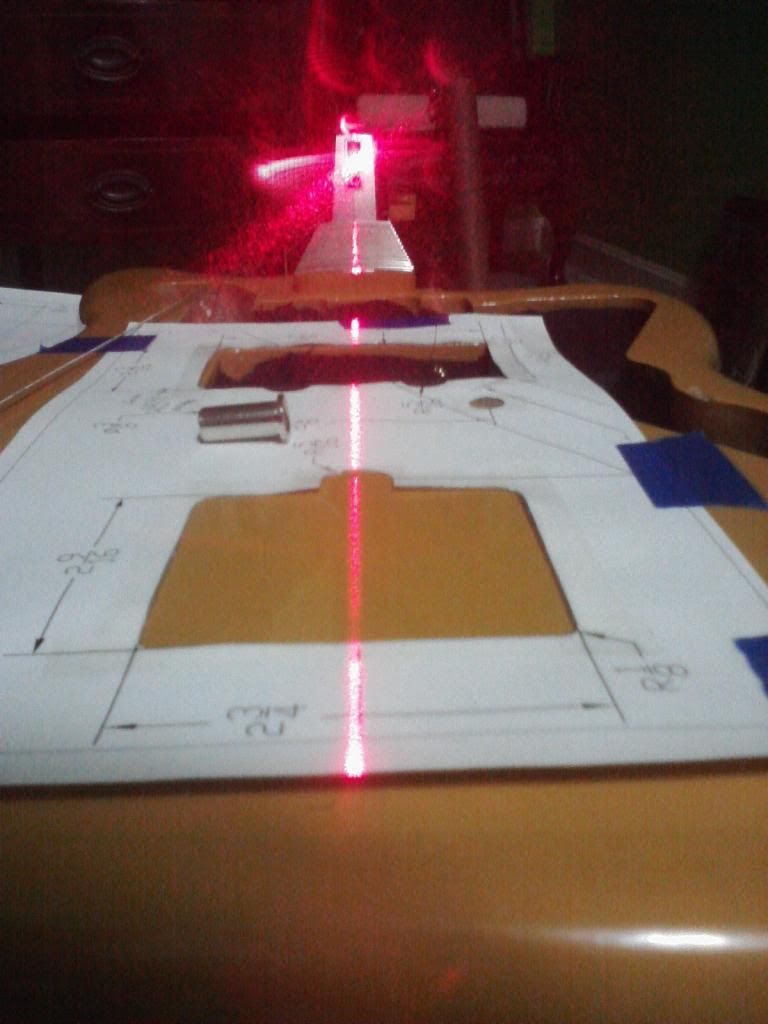

Next, set up one of these cheap-ass laser markers (or something similar)

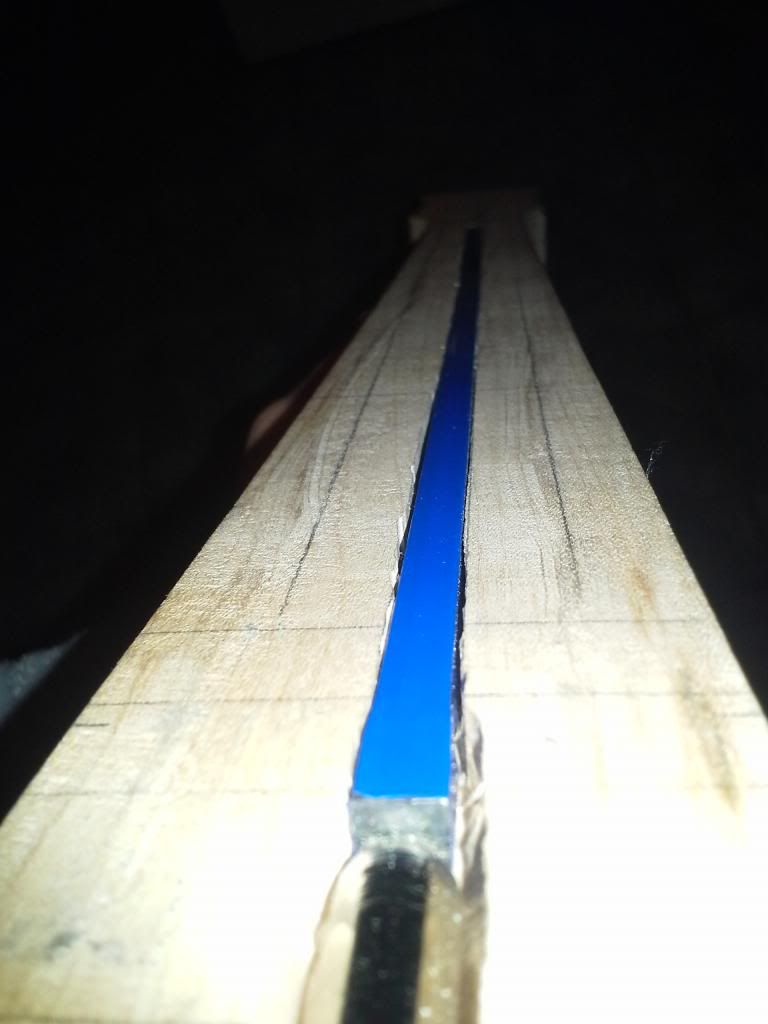

so it intersects the router bit at a 90* angle to your guide clamps. I set it up so that I push the blank into the bit and stop when my slot-end mark hits the laser line. I make several passes, each deeper than the last, until it's the proper depth. If my bit is wider than the rod, I shim the slot with veneer strips. I do the same thing if I cut a little too deep.

It'll take some practice to get comfortable with the process, but the results seem to be consistent.

Hope this helps. I'll see if I can't document this on my next neck build.